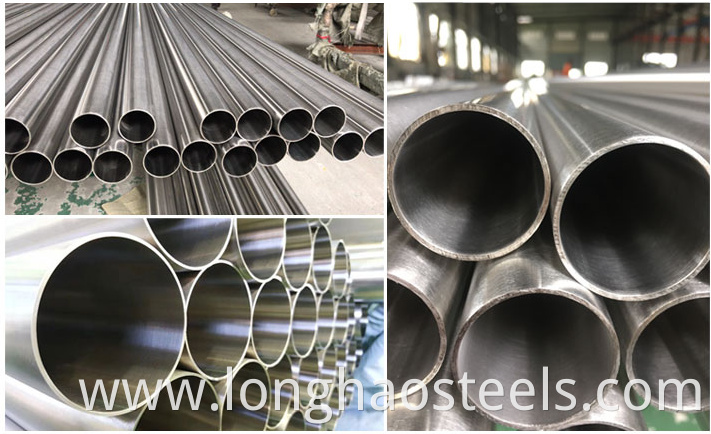

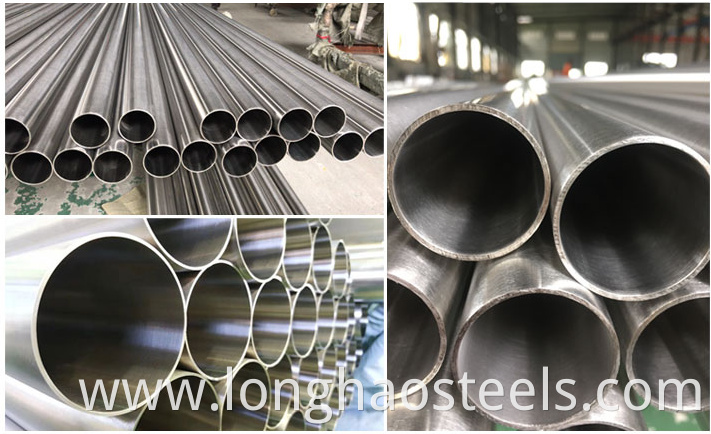

A hollow round Stainless Steel Pipe is a cylindrical tube made of Stainless Steel that has a hollow center. It is commonly used in industrial and construction applications where a strong, durable, and corrosion-resistant material is required. Stainless steel is an alloy of iron, carbon, and other elements, including chromium, which gives it its corrosion-resistant properties. The hollow center of the pipe allows for the passage of fluids, gases, or other materials. Hollow round stainless steel pipes come in various sizes, wall thicknesses, and lengths, and can be welded or seamless. They are commonly used in industries such as oil and gas, chemical processing, food and beverage, and pharmaceuticals.

| Material | 201,302,303,304,304l,316,316l,321,309s,310s,904l etc |

| Size(round pipe) | 9.5-219 mm or customized |

| Size (square pipe) | 10×10-150×100 mm or customized |

| Size (oval pipe) | 30×15,80×40 mm or customized |

| Thickness | 0.24-3 mm |

| Length | 6m or according to customer’s request |

| Outer diameter | 8-219mm |

| Tolerance | Outer diameter :±0.2mm Thickness :±0.02mm Length :±0.5mm |

| Process method | Code drawn, annealed with nitrogen protection, ultrasonic,automatic shape, polished |

| Finishing | A: sanded B: 400#-600# mirror C: hairline brushed D: TIN titanlumE : HL brushed & mirror (two kinds of finishing for one pipe)

|

| Round Steel Tube Specification |

| Nominal Diameter | Inch Outside Diameter | Outside Diameter | Wall Thickness |

| 15 | 1/2 | 20-22 | 0.7-2.75 |

| 20 | 3/4 | 24-26.5 | 0.7-2.75 |

| 25 | 1 | 31-33.4 | 0.7-3.75 |

| 32 | 1 1/4 | 40-42.5 | 0.7-4.0 |

| 40 | 1 1/2 | 46-48.3 | 0.7-7.0 |

| 50 | 2 | 57-60.3 | 0.7-7.0 |

| 65 | 2 1/2 | 74-76.3 | 0.7-7.0 |

| 80 | 3 | 86-89 | 0.7-8.0 |

| 100 | 4 | 111-114 | 0.8-9.0 |

| 125 | 5 | 138-140 | 0.9-9.0 |

| 150 | 6 | 164-165 | 1.0-11.5 |

| 200 | 8 | 218-219 | 1.1-12 |

| Surface Treatment |

| Finish | Thickness | Characteristics | Applications |

| No.1 | 3.0mm~50.0mm | Finished by hot-rolling,annealing and pickling.characterized by white pickled surface | Chemical industry equipment Industrialtanks |

| No.2B | 0.3mm~6.0mm | Finished by heat treatment, pickling after cold rolling,followed by skin pass line to be more brighter and smooth surface | General Application Medical InstrumentsTableware |

| No.BA | 0.5mm~2.0mm | Bright heat treatment after cold rolling | Kitchen utensil, kitchen ware,architectural purpose |

| No.4 | 0.4mm~3.0mm | Polishing with No150toNo.180 mesh abrasives.The most popular finishes | Milk &Food processing acilities,Hospital Equipment Bath-tub |

| No.8 | 0.5mm~2.0mm | A mirror-ike reflective surface by polishing with finer abrasives over 800 mesh | Reflector, Mirror, Interior- Exterior decoration for building |

| HL | 0.4mm~3.0mm | Finished by continuous linear polishing | Architectural purposes, escalators.kitchen ware

vehicles |