Grade: DC51D

DC51D Galvanized Steel Chemical composition:

Chemical composition % of DC51D

| C | Si | Mn | P | S | Ti |

| max 0.10 | - | max 0.50 | max 0.035 | - | -

|

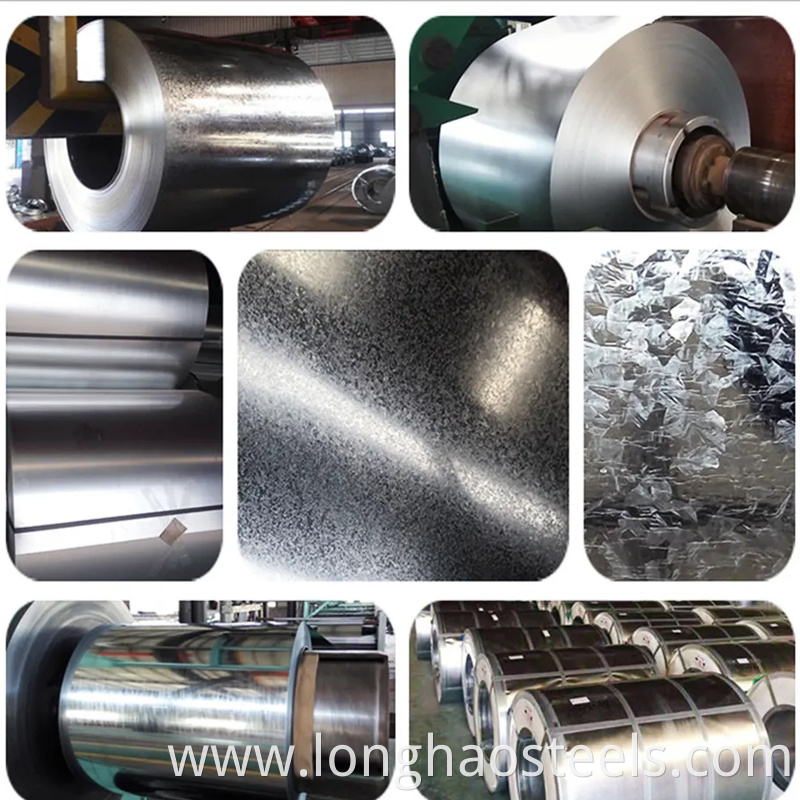

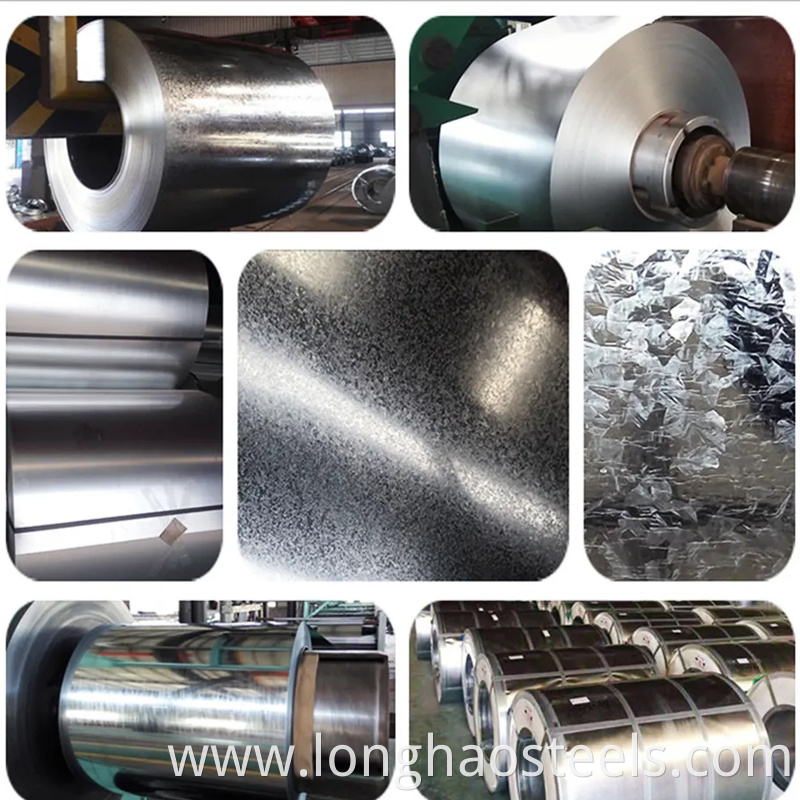

Galvanized steel Coil

Hot dipped galvanized steel sheet and alloying Galvanised Plate have excellent performance, possessing ideal comprehensive of corrosion resistance, formation and coating. They are mainly used in building-roof, door, window, roller shutter door and suspended skeleton, automobiles-vehicle shell, chassis, door, truck lid, oil tank, and fender, metallurgy-steel sash blank and color coated substrate, etc; In electrical appliance, it is mainly for fridge seat, shell, freezer and kitchen equipment. The company has set up 350,000T/Y continuous galvanizing equipment, with UEC technique and smoothing, straightening, passivating and coating functions to produce various Galvanized Steel Plate with thickness 0.12-1.2mm and width 700-1250mm.

| Standard | AISI,ASTM,GB,JIS | Material | SGCC,S350GD+Z,S550GD+Z,DX51D,DX52D,DX53D |

| Thickness | 0.12-1.2mm | Width | 600-1500mm |

| Tolerance | +/-0.02mm | Zinc coating AZ | 20-500g/m2 |

| Hardness | Soft hard(60),medium hard(HRB60-85),full hard(HRB85-95) |

| Technique | Hot rolled, cold rolled | Delivery | 15-30 days |

| Certification | ISO 9001-2008,SGS,CE,BV | MOQ | 25 TONS (in one 20ft FCL) |

| Surface treatment: | Chromated, Oiled |

| Spangle | regular spangle,minimal spangle, zero spangle,big spangle |

| Payment | 30%T/T in advanced+70% balanced;irrevocable L/C at sight |

| Remarks | Insurance is all risks and accept the third party test |

| Mechanical properties of galvanized steel |

| Usage | Grade | Yield strength(MPa) | Tensile strength(MPa) |

| Punching galvnaized steel | DC51D+Z | - | 270-500 |

| DC52D+Z | 140-300 | 270-420 |

| DC53D+Z | 140-260 | 270-380 |

| Structure galvanized steel | S280GD+Z | ≥280 | ≥360 |

| S350GD+Z | ≥350 | ≥420 |

| S550GD+Z | ≥550 | ≥560 |

Other products:

Stainless Steel Coil, carbon steel coil